Power Over Ethernet (PoE) Cable Solutions

Solutions for Today’s Advanced Remote Powering Applications

The ability to deliver DC power to IP-based devices over twisted-pair copper cabling using remote powering technology like Power over Ethernet (PoE) and Power over HDBaseT (POH) has made a significant impact on today’s network infrastructure deployments. Today more than 100 million PoE-enabled ports are shipping annually, and it’s no wonder considering the benefits that remote powering delivers – faster deployment, 75% less cost than an AC power run and the ability to receive centralized back-up power, just to name a few.

The first generation of PoE, IEEE 802.3af Type 1 (15W), was used for powering lower-power devices like IP clocks, VoIP phones and simple security cameras. With the development of IEEE 802.3at Type 2 (30W), higher level IEEE 802.3bt Type 3 (60W) and Type 4 (90W), and POH (100W) for AV applications, remote powering technology now powers everything from wireless access points, advanced pan-tilt-zoom cameras, access control devices and LED lights, to video displays, point of sale machines and even computers and laptops.

With today’s higher levels of remote powering comes the potential for heat buildup within cable bundles and electrical arcing damage to connector contacts, which can lead to power and efficiency losses, performance degradation and the potential for damaged connecting hardware. Deploying a cabling infrastructure for today’s converged networks that deliver remote power to a wide range of devices requires cables and connectivity designed to provide superior remote powering support – that’s Siemon’s PowerGUARD® technology.

“The Siemon team feels very privileged to have supported this latest project with Curtin University. It has delivered a next-generation structured cabling infrastructure, that unlocks all the benefits of a PoE-enabled network. This upgrade provides the university with a quality, high performance and future-ready foundation, that will allow students and staff to enjoy the best experience possible while in that environment for many years to come.”

Ben Mok, State Manager for Western and Southern Australia at Siemon

Read Case Study

How to Support PoE Applications

In this tech brief, you will learn how Siemon solutions provide the best performance with the easiest installation practice.

Read more

Innovative Outlet Design

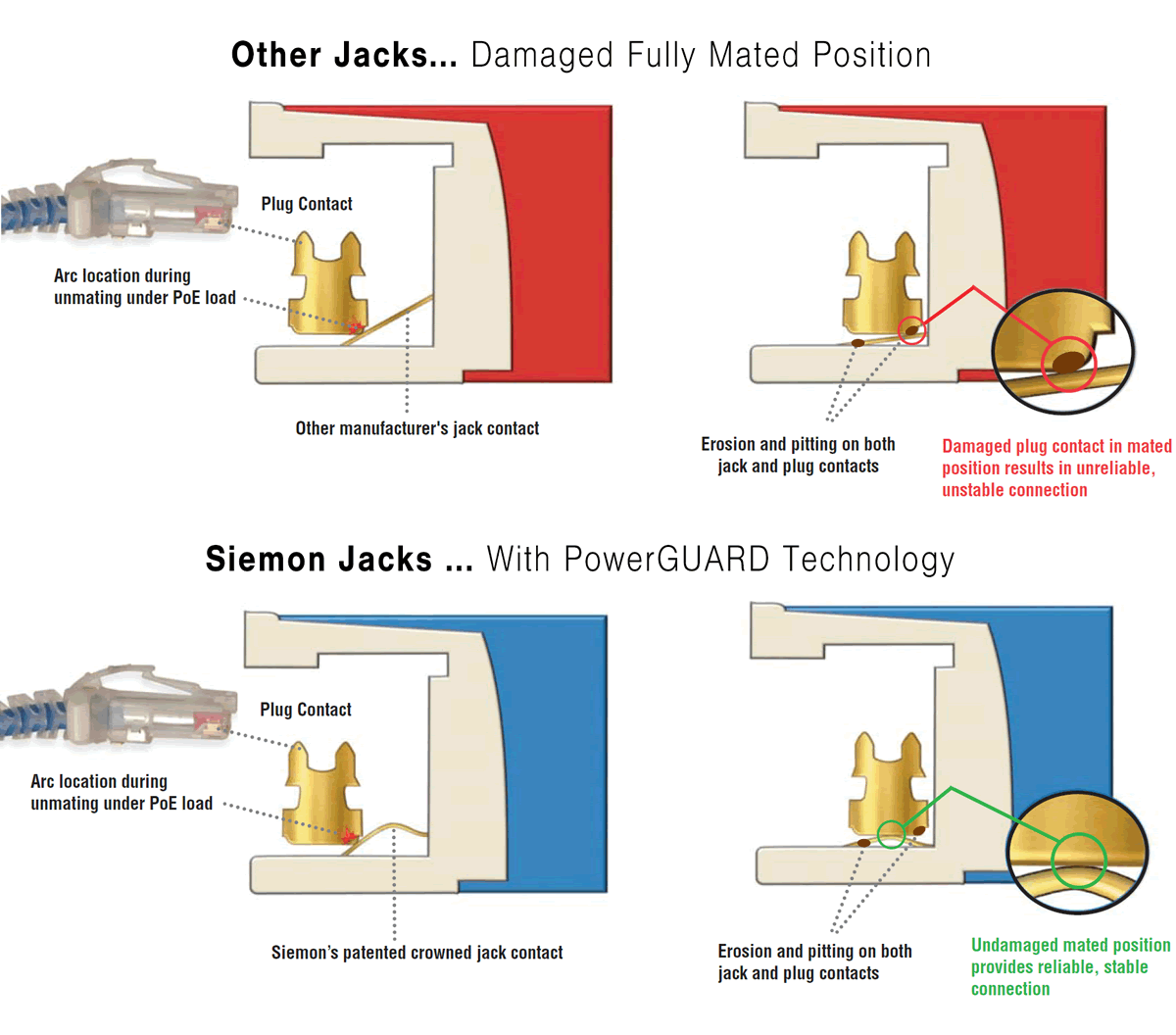

Contacts in RJ-45 connecting hardware are plated (typically with gold or palladium), and unmating a jack-plug connection while transmitting PoE or POH produces an arc that erodes the plated jack-plug contact surfaces at the arcing location. When this erosion occurs in the area of the fully mated position on an RJ-45 connector, the result is an unreliable connection that can cause degraded network performance and increased bit error rates.

Some connecting hardware manufacturers have succeeded in ensuring that arc location on the jack contact is separate from the fully mated position. Unfortunately, their contact geometry does not ensure that erosion on plug contacts is also away from the fully mated position. Erosion on either the jack or plug contacts results in an unreliable connection.

Siemon’s UltraMAX™, Z-MAX®, MAX® and TERA® jacks with PowerGUARD technology feature a patented crowned jack contact shape that places arcing damage to both the plug and jack contacts away from the final mated position-allowing you to connect and disconnect to the latest remote powering applications with zero risk.

Advanced Cable Construction

Remote powering applications can exhibit temperature rise within bundled cable configurations, which is even more of a concern in higher power Type 3 and Type 4 PoE and POH applications. Temperature rise can increase in insertion loss and premature aging of jacketing materials that can have an irreversible effect on transmission performance.

The temperature dependence of cables is recognized in cabling standards and both TIA and ISO specify an insertion loss length de-rating factor at temperatures above 20°C (68°F). Reducing link length to meet these requirements can impact infrastructure design strategies and flexibility. In addition, for remote powering applications greater than 60W, the National Electric Code® (NEC) restricts the number of cables allowed in a bundle based on the size (AWG) and temperature rating of the cable.

Siemon’s Category 6A Gap Technology (GT) UTP with a discontinuous foil construction, Category 6A shielded and Category 7A fully-shielded cables with PowerGUARD technology are qualified for mechanical reliability in high temperature environments up to 75° C, ensuring superior heat dissipation and extremely stable transmission performance, enabling decreased length de-rating as shown in the graph and reduced bundling requirements.

High-performance Device Connections

Modular Plug-Terminated Links

In a traditional network infrastructure, IP devices typically connect to the network via doubled-ended patch cords from outlets that are terminated to horizontal cables. For some devices, especially those mounted to a ceiling that tend to be permanently fixed, the traditional method is not always the most efficient. Devices such as PoE lights, security cameras and wireless access points can instead be connected directly via a standards-based modular plug-terminated link (MPTL), eliminating the faceplate, outlet and patch cord. The MPTL configuration simplifies bills of materials, allows for custom-length quick connections, improves performance by reducing extra connection points and improves security by eliminating patch cords that can be easily disconnected.

For PoE-enabled devices connected via an MPTL configuration, Siemon’s Z-PLUG Field Terminated Plug with PowerGUARD technology offers superior performance with its fully-shielded 360-degree enclosure and 75°C operating temperature for superior heat dissipation in conjunction with Siemon PowerGUARD cables.

- Exceed Category 6A performance to support high-speed applications like Wi-Fi 5 and 6

- Terminates to UTP, solid and stranded 22 to 26 AWG cable – all with a single part number

- Shorter plug design with rounded edges and ability to eliminate the boot and latch protector makes it ideal for connecting to devices with limited space

- The user-friendly Z-PLUG termination tool and intuitive hinged lacing module that eliminates cable feed through enables best-in-class termination speed

Patch Cord Connections

If not using an MPTL configuration, Siemon Z-MAX Category 6A and TERA Category 7A four-pair shielded solid modular cords with PowerGUARD technology are ideal for connections from the outlet to the device. With a 75°C operating temperature, these solid conductor cords are less likely to exhibit degraded transmission performance at elevated temperatures, making them ideal for use in spaces that do not have environmental control (e.g., ceilings and warehouses).

For use within environmentally controlled spaces, such as active equipment and cross-connect connections within the telecommunications closet, Siemon Category 6A shielded stranded modular cords with PowerGUARD technology are also qualified to a higher operating temperature of 75°C, while offering a smaller diameter and greater flexibility for use within patching fields.

Featured PoE Products

<meta name="addsearch-custom-field" content="source=web" />

<meta name="addsearch-custom-field" data-type="text" content="lang=en" />

<meta name="addsearch-custom-field" data-type="text" content="regions=North America;regions=Europe Central Asia;regions=Asia Pacific;regions=India Middle East Africa" />

<meta name="addsearch-custom-field" data-type="text" content="category=environment" />