Siemon recently announced its TERA single-pair Ethernet (SPE) cabling system supports 10BASE‑T1L over distances of up to 400 meters. This fully-shielded solution offers superior noise immunity, virtually zero emissions and so much transmission headroom that the need for field testing is eliminated.

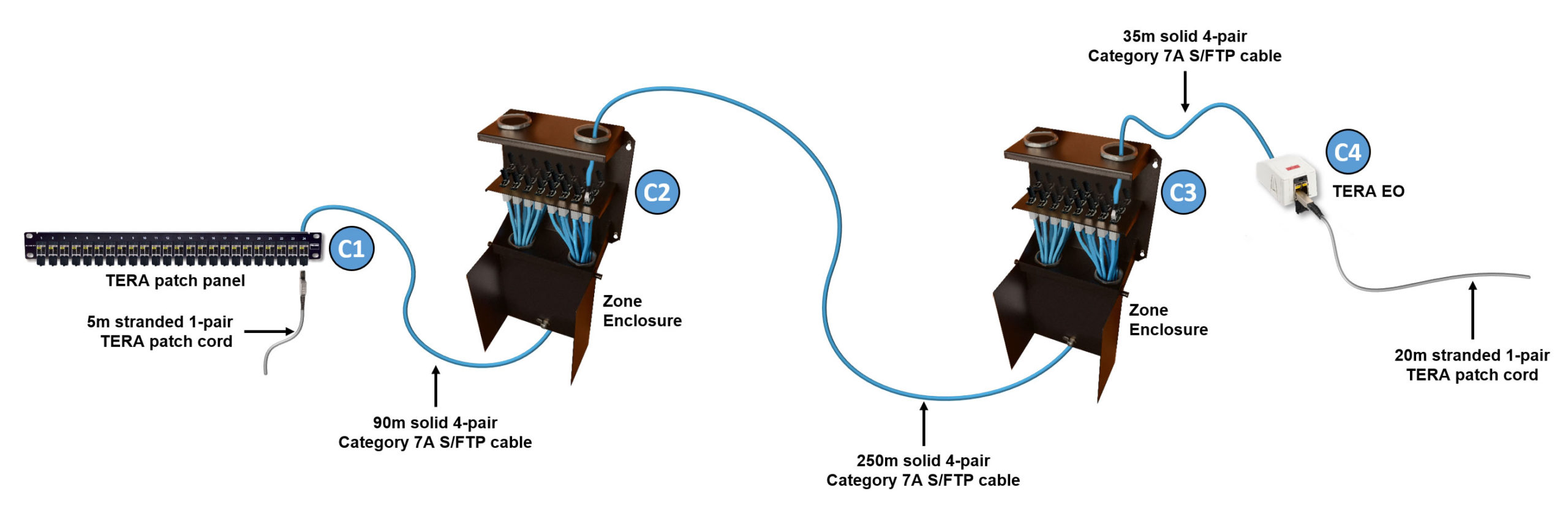

To demonstrate typical transmission performance for this system, Siemon Labs collected transmission data for 400m SPE channels consisting of 4 TERA connectors, 375 m of solid category 7A S/FTP 4-pair cable, and 25 m of stranded 1-pair TERA patch cords. Each pair in the 4-pair cable was tested, with the 1‑pair TERA patch cords cycled thru each quadrant of the 4-pair TERA connectors in positions C1, C2, C3 and C4 as shown in Figure 1.

Figure 1 – TERA SPE 400m Channel

Component List

- C1, C2, C3, and C4 = TERA 4-pair outlet (part no. T7F-01-1)

- 5m of stranded 1-pair shielded TERA patch cord (part no. T1-XXM-B06L)

- 90m of solid 4-pair category 7A S/FTP cable (part no. 9T7P4-E10-06-R1)

- 250m of solid 4-pair category 7A S/FTP cable (part no. 9T7P4-E10-06-R1) with TERA 4 pair field terminatable plugs (part no. T7P4-B01-1) at each end

- 35m of solid 4-pair category 7A S/FTP cable (part no. 9T7P4-E10-06-R1)

- 20m of stranded 1-pair shielded TERA patch cord (part no. T1-XXM-B06L)

The test results demonstrate that all four 400m TERA SPE channels exceed the requirements for 10BASE‑T1L specified in IEEE Std 802.3cg™-2019 by impressive margins. For example, the measured headroom for the key system parameter of insertion loss is greater than 45%. SPE channel performance is also specified in the developing ISO/IEC 11801-1 Amendment 1 and ANSI/TIA-568.5 Standards. The 400m TERA SPE channels also exhibit substantial headroom to these draft requirements.

The test report also confirms that the TERA mated connection provides current carrying capacity up to 2 Amps per conductor when tested in accordance with IEC 60512-99-002. The report is available upon request from Siemon Technical Services.

Full details on how existing TERA permanent links can easily be retrofitted to support 10BASE‑T1L applications, as well as how to specify new generic TERA permanent links capable of supporting both future IT and OT device connections and dedicated SPE device connections, can be found here: “TERA® SPE Deployment Solutions for Retrofit, Future-Proof New, and Day 1 SPE Installations“.

Mike Boisseau

Business Unit Leader - Copper Systems

Mike Boisseau joined The Siemon Company in 2006 and has held various roles within the product management group supporting most major product lines during his 17 years with the company. Over the last 10+ years, Mike has lead Siemon’s Copper Business Unit and more recently took on leading the Global Project Pricing team. Mike supports Siemon’s efforts to provide quality solutions to customers around the globe and is based at corporate headquarters in Watertown, CT.

<meta name="addsearch-custom-field" content="source=web" />

<meta name="addsearch-custom-field" data-type="text" content="lang=en" />

<meta name="addsearch-custom-field" data-type="text" content="regions=North America;regions=Europe Central Asia;regions=Asia Pacific;regions=India Middle East Africa" />

<meta name="addsearch-custom-field" data-type="text" content="category=blog" />